The EDS provides on-site treatment of chemical warfare materiel in a safe, environmentally sound manner. As an innovative alternative to the open detonation of explosively configured munitions, the EDS supports both planned and quick-response munition recovery operations.

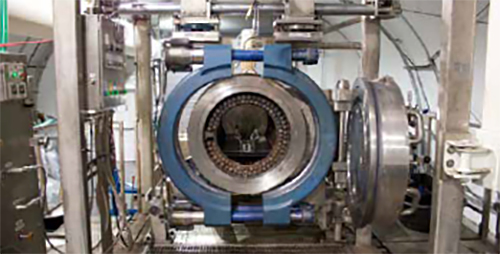

The EDS uses cutting charges to explosively access chemical munitions, eliminating their explosive capacity before neutralizing the chemical agent. The system’s main component, a sealed, stainless-steel vessel, contains all the blast, vapor and fragments from the process. Operators confirm treatment by sampling residual liquid and air from the vessel prior to reopening the EDS.

The success of the first EDS, known as EDS Phase 1, led to the development of a family of EDS units with mission-specific capabilities. The EDS Phase 2 was constructed to contain larger materiel in both size and explosive content. Both systems are trailer-mounted and transport easily where needed.

The EDS site layout, set up in accordance with all applicable laws and permit requirements, ensures the overall safety of the workers and the environment. Continuous air monitoring conducted at every EDS site ensures protection. The U.S. Army Chemical Materials Activity Recovered Chemical Materiel Directorate takes all precautions seriously during operations, and safety remains the top priority.